In a world driven by technology and automation, there is a growing appreciation for the harmonious combination of craftsmanship and cutting-edge techniques in the creation of products. Acrylic, a versatile and visually stunning material, exemplifies this synergy perfectly. The production of acrylic products involves a delicate balance between traditional handcrafting and advanced technology, resulting in exquisite and functional items that cater to a wide range of applications.

I. Acrylic: A Modern Wonder Material

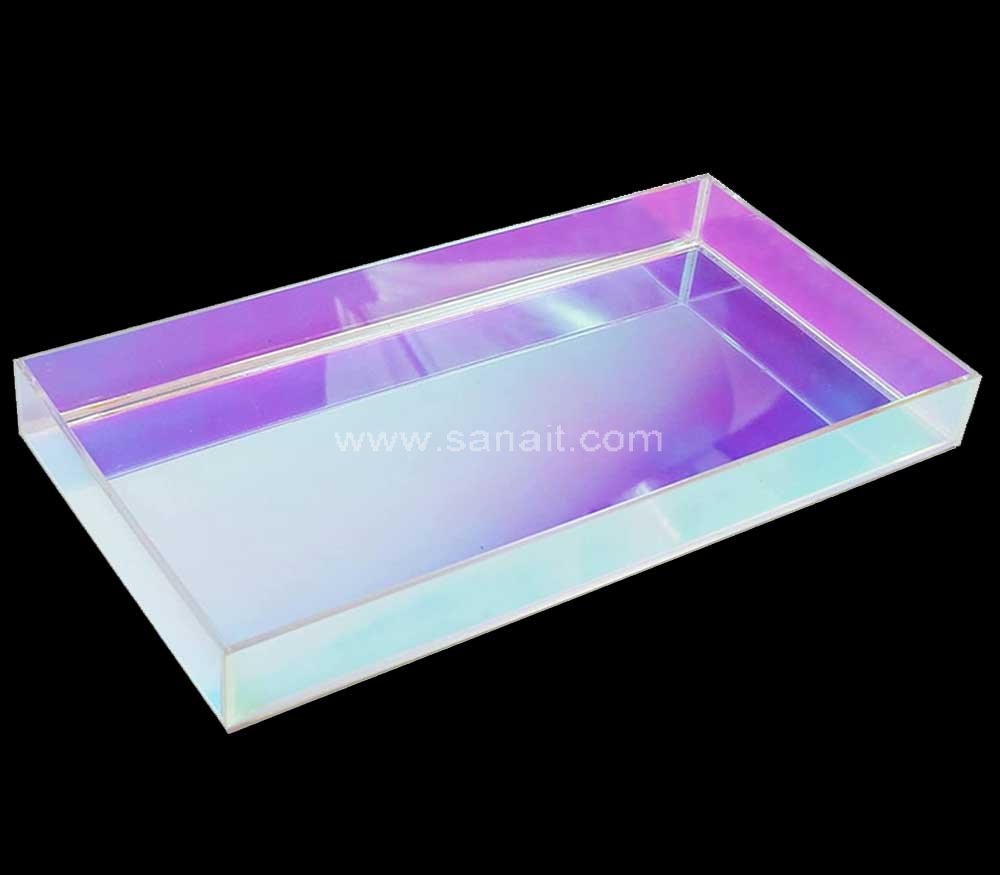

Acrylic, also known as polymethyl methacrylate (PMMA), is a transparent thermoplastic known for its exceptional clarity, durability, and versatility. It can be found in a myriad of applications, including signage, furniture, lighting fixtures, and even prosthetic devices. Its unique combination of properties makes it a sought-after material for both aesthetic and practical purposes.

II. The Role of Craftsmanship

- Design and Conceptualization

The creation of acrylic products begins with a spark of creativity and design. This phase heavily relies on the skill and vision of craftsmen and designers. Craftsmen draw on their experience and artistic flair to conceptualize products that not only meet functional needs but also exhibit aesthetic appeal.

- Material Selection

Selecting the right type of acrylic is crucial. Craftsmen must consider factors such as transparency, thickness, color, and special properties like UV resistance or flame retardance. This decision impacts the final appearance and functionality of the product.

- Cutting and Shaping

Craftsmanship plays a pivotal role in the cutting and shaping of acrylic sheets. While machines can perform these tasks with precision, skilled artisans are often required to create intricate designs, curves, and custom shapes. Craftsmen use tools like saws, routers, and laser cutters to achieve the desired forms.

III. The Integration of Technology

- Digital Prototyping

Technology steps in during the prototyping phase. Advanced software enables craftsmen to create 3D models of their designs. These digital prototypes help in refining the product’s appearance and functionality, allowing for precise adjustments before physical production begins.

- CNC Machining

Computer Numerical Control (CNC) machines are employed to cut and shape acrylic sheets with remarkable precision. These machines follow the exact specifications from the digital prototypes, ensuring uniformity and accuracy in production. CNC machining allows for the creation of complex and intricate designs that would be challenging to achieve solely through manual methods.

- Thermal Forming

Acrylic’s unique property of becoming pliable when heated makes it ideal for thermal forming. This process involves using heat to bend and mold acrylic sheets into specific shapes. Technology-controlled ovens ensure consistent heating, while craftsmen use their expertise to manipulate the softened material into its final form.

IV. Quality Control

Craftsmanship remains at the forefront when it comes to quality control. Skilled artisans inspect each piece for imperfections, ensuring that the product meets the highest standards of clarity, precision, and finish. Any defects are meticulously corrected by hand to guarantee the final product’s excellence.

V. Conclusion: The Artistry of Acrylic

The production of acrylic products is a testament to the harmonious blend of craftsmanship and technology. It begins with a vision and artistic talent, transitions into a digital realm of precision, and returns to the skilled hands of craftsmen for the finishing touches. The result is not just a functional item but a work of art that seamlessly integrates into modern life, enriching our surroundings with its clarity, elegance, and purpose. The fusion of traditional craftsmanship and contemporary technology in acrylic product manufacturing exemplifies the boundless possibilities that arise when human creativity meets the power of innovation.