Creating jewelry is a form of art that allows artisans to express their creativity through the design and fabrication of unique pieces. Acrylic jewelry, known for its versatility and modern appeal, has gained popularity in recent years. In this article, we will delve into the fascinating process of crafting acrylic jewelry, from the initial design concept to the final, polished piece.

Design Concept and Inspiration

The journey of crafting acrylic jewelry begins with a concept or inspiration. Designers often draw ideas from nature, architecture, personal experiences, or even current fashion trends. The initial concept serves as the foundation for the entire creative process, guiding decisions regarding shape, color, and style.

Material Selection

Acrylic jewelry makers have a wide range of acrylic sheets to choose from, each with its unique characteristics. Transparent, translucent, and colored acrylic sheets offer diverse options for creating stunning jewelry pieces. The choice of material depends on the designer’s vision and the desired final product.

Cutting and Shaping

Once the design is finalized and the acrylic sheet selected, the next step involves cutting and shaping the material. Various techniques, such as laser cutting, sawing, or hand cutting, can be employed to transform the acrylic sheet into the desired shape. Precision is key, as even slight imperfections can affect the final aesthetics of the jewelry.

Engraving and Personalization

Acrylic jewelry can be further personalized through engraving. Intricate designs, names, or meaningful symbols can be etched onto the acrylic surface. Engraving adds a unique touch to each piece and allows for customization, making the jewelry more special to the wearer.

Assembling Components

Many acrylic jewelry designs involve multiple components, such as pendants, beads, and connectors. These components are assembled using various techniques like gluing, riveting, or threading. Attention to detail during this step ensures that the final piece is both aesthetically pleasing and structurally sound.

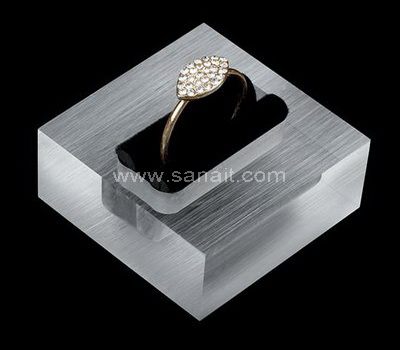

Polishing and Finishing

The surface of acrylic jewelry often requires polishing to achieve a smooth and glossy finish. Sanding and buffing are common techniques used to remove any imperfections, ensuring that the jewelry piece shines and feels comfortable to wear.

Coloring and Painting

Acrylic jewelry can be further enhanced with coloring and painting. This can be achieved through techniques like hand-painting or applying colored layers of acrylic to the base material. The choice of colors can evoke specific emotions or complement the design’s overall theme.

Adding Hardware

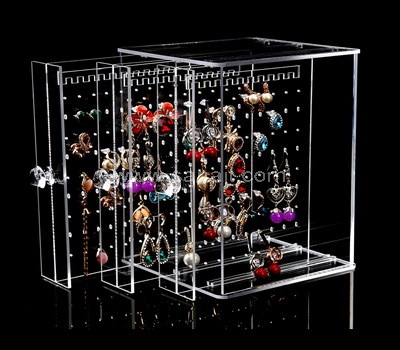

Hardware components, such as earring hooks, clasps, or chains, are added to complete the jewelry piece. These elements not only serve a functional purpose but also contribute to the overall design. Their selection should harmonize with the jewelry’s aesthetics.

Quality Control and Inspection

Before being offered to the market, each acrylic jewelry piece undergoes a thorough quality control process. Designers and artisans carefully inspect the piece for any defects, ensuring it meets the highest standards of craftsmanship.

Packaging and Presentation

The final step in crafting acrylic jewelry is packaging and presentation. Designers pay special attention to the packaging, as it sets the tone for the entire customer experience. The jewelry is often placed in a decorative box or pouch, ready to be presented to the delighted wearer.

Conclusion

The creation of acrylic jewelry is a labor-intensive and creative process that melds artistry with craftsmanship. From concept and material selection to shaping, engraving, assembling, and finishing, each step plays a crucial role in transforming acrylic sheets into unique and personalized jewelry pieces. Acrylic jewelry continues to captivate individuals with its modern and customizable aesthetic, making it a sought-after choice for those looking to express their individuality through wearable art.