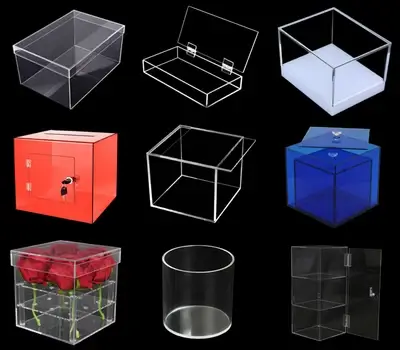

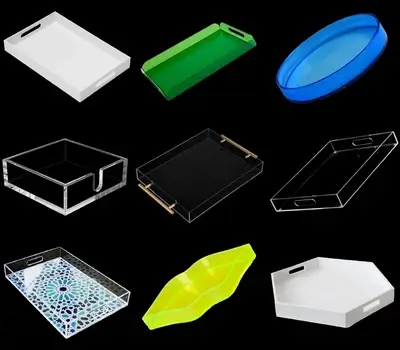

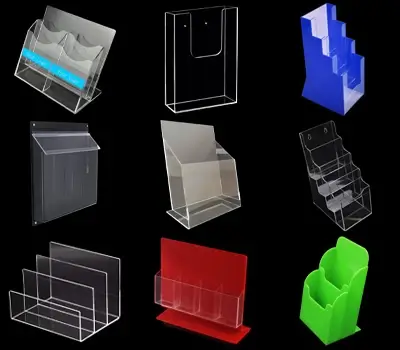

Custom Acrylic Boxes, Acrylic Display Stands

Some of Our Examples

Why Choose us

Factory Direct

No middleman, competitive price, help you save a lot of money!

Quality Guaranteed

We provide a differentiated service that is worth paying for.

Custom Made

Just please tell us what you need, we can create it for you.

On Time Delivery

All our customers always receive the goods before the agreed date.

Worldwide Shipping

Wherever you are, we can deliver the goods by sea or by air.

Who We Are

Custom Acrylic Boxes & Acrylic Display Stands Manufacturer

Sanait Co., Ltd is a China manufacturer of premium quality custom acrylic boxes and acrylic display stands solutions based in Dongguan City, Guangdong Province, China. We specialize in customizing acrylic display shelf stand, bespoke acrylic boxes, personalized acrylic block, makeup display organizer, lucite serving tray, and wide range of other products to cater to the needs of various industries. Our products are shipped globally, with our main markets being the United States, Europe, Australia, and the Middle East.

Our state-of-the-art facility is equipped with a vast stock of raw material, allowing us to process orders quickly and efficiently. Our wide range of products includes POS stands, POp displays, perspex stand, plexiglass boxes, lucite blocks, serving trays, packaging boxes, perspex display box, clear cases, makeup organizer, cosmetic stands, brochure holder, jewelry stands, pedestal risers, photo frames, plexi sign holders, table acrylic stand, plexiglass stand holder, perspex holders, perfume display, plinth stand, and more. Each item is crafted to meet the highest quality standards and delivered at a competitive price. Regardless of the size and shape of your product, we can provide a suitable solution.

Our team of experienced professionals, including engineers, designers, manufacturers, craftsmen, project managers, and marketing experts, ensures that your ideas are brought to life. With our expertise and knowledge, we can help you conceive, design, prototype, manufacture, assemble, and complete products that meet your specific requirements. Whether you are looking for any acrylic products, we are your best resource.

How To Customize?

Tell us what you need via email sales@sanait.com, or send us online inquiry via Contact Form. If you have a drawing / design file / picture, etc, that would be great. If you only have an idea, it is also no problem, we can help you to design.

2. Quotation

Our sales team will quote quickly according to product size, material requirements, order quantity, etc.

3. Prototype

Prototype (sample) is available if you accept our quotation and would like to pay for sample cost and shipping cost. The sample is free of charge (not including shipping) if the value is less than 10USD.

4. Mass Production

After customers approved the prototype and make deposit, we will produce the mass goods and continuously provide the corresponding production information to the customer.

5. Delivery

After the mass products were completed, we will show detailed production photos to customers, then the customer pays for the balance. If customers have their own forwarder, they can handle the shipping by themselves. Or we can handle the shipping.

6. After-sale Service

We promise 100% quality guarantee for all of our products. If there are any questions after your received the goods, please don't hesitate to let us know, we will help you as soon as we can.